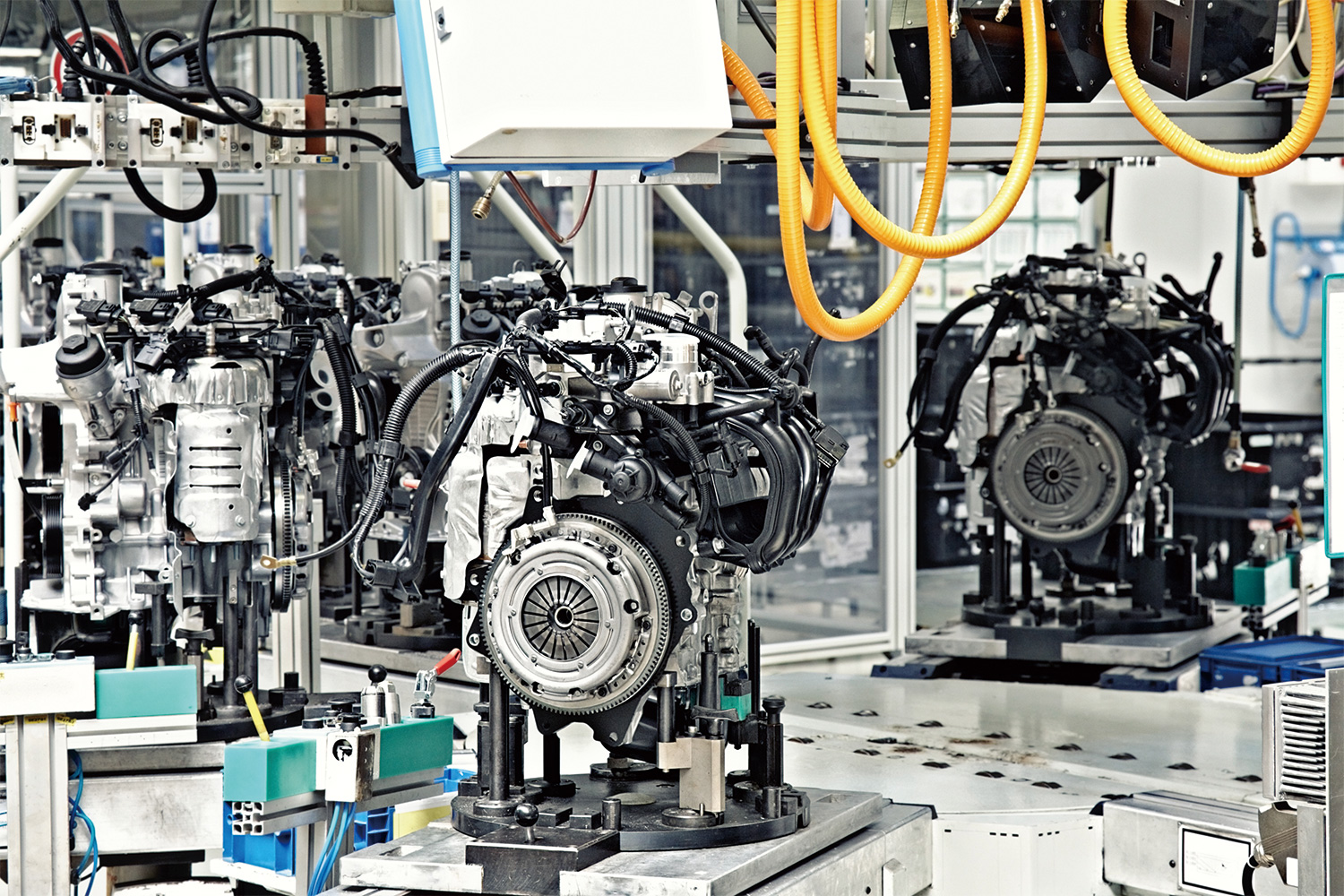

The Nitto Kohki "CUPLA" is used in all stages of automotive manufacturing - pneumatics and hydraulic fluid lines, multiple port connections systems and made-to-order custom items. Nitto Kohki has been making fluid connection innovations for production efficiency for over 60 years.

Application Examples

Nitto Kohki's high quality non-grease couplings are used in chemical transfer system of electrolyte for lithium ion battery production, high purity water and specialty chemicals for semiconductor manufacturing processes. Semicon Cupla body material includes PFA, PTFE, and electro-polished 304, 316 stainless steel for corrosion resistance against various types of chemical. All Semicon Cupla products are grease-free design and its components are cleaned, assembled, inspected, and packed in a clean room to maintain the high purity.

Application Examples

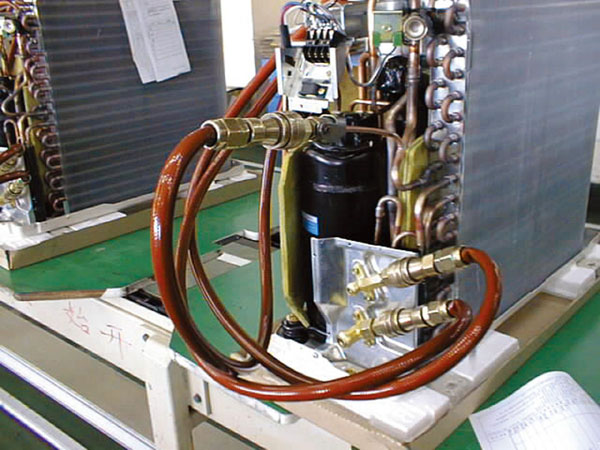

Nitto Kohki has wide range of Pipe Cupla and Charge Cupla series designed for HVAC production. SP-V Cupla has unique valve structure achieving high flow rate, great seal tightness even in vacuum application. Various types of body and sealing material are available for all refrigerant types. Nitto Kohki also custom-designs for pipes of any shape and thread upon request.

Application Examples

A large offering is available from Nitto Kohki for the high pressure metal casting and plastic injection molding marketplace. Our 350 Cupla, Flat Face Cupla (F35, FF) designed for high pressure die casting (HPDC) machinery are one of the most durable quick connect couplings in the world-wide market. Our range includes multiple port connection system for cooling lines, pneumatic lines for ejector pin or valve gating process. Our top performance and durability provides benefits for each stage of production, improve casting cycle time, and reduced downtime.

Application Examples

Nitto Kohki offers a new product series, Compact Zerospill Cupla. Compact Zerospill Cupla has a flat face design with high-flow, low-spillage characteristics. It is designed for High Performance Computer (HPC) cooling application within data analytics & AI technology market, as well as telecommunication systems and data storage systems. Its flow coefficient (Cv) has been established as the highest compared to competing brands. This benefit allows for more efficient heat removal, greater rack density, improved system performance and reduced power consumption.

Application Examples