Pump Division

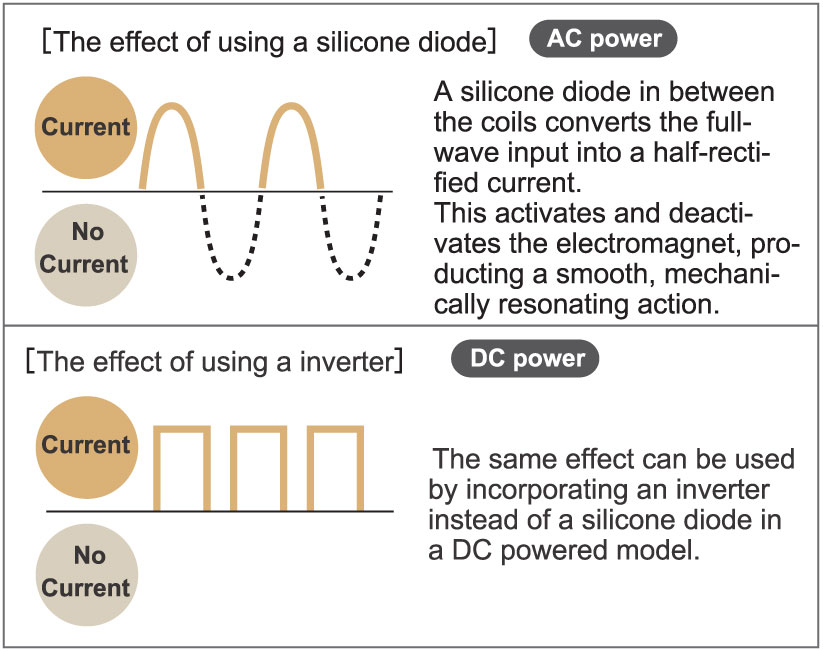

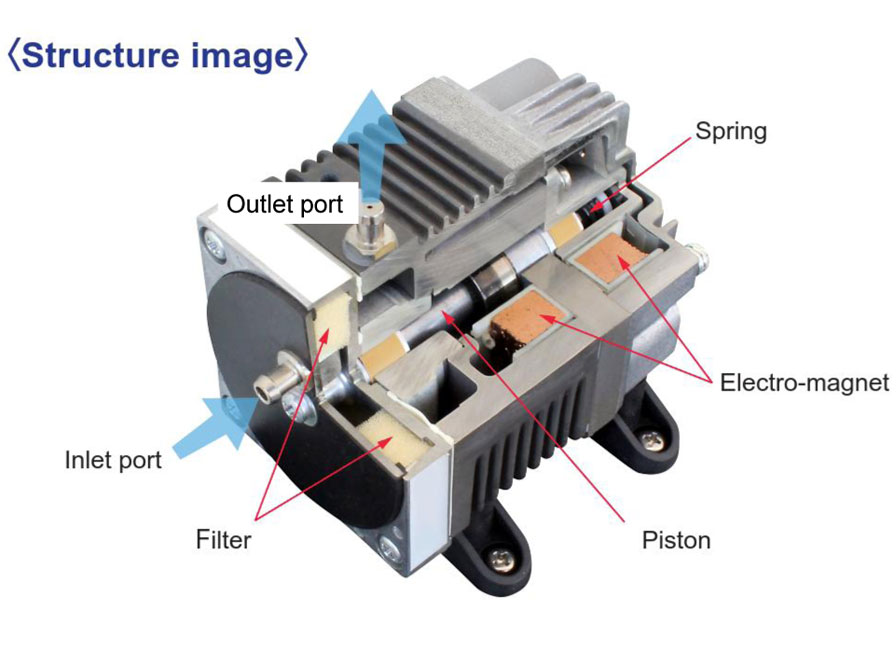

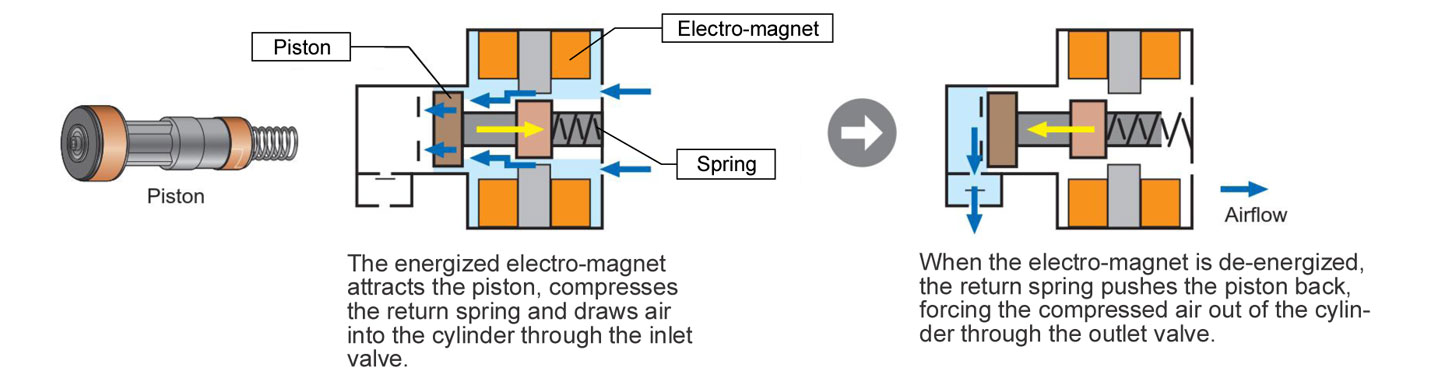

The electro-magnet and return spring alternately drive the piston inside the cylinder, the mechanical resonance of which is synchronized with the input current cycle.

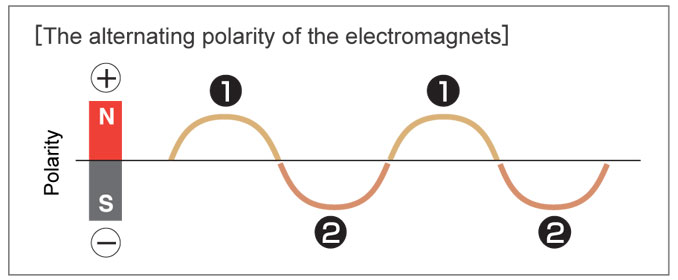

There are AC models that use AC waveform and a silicon diode, and DC models that use DC waveform and an inverter.

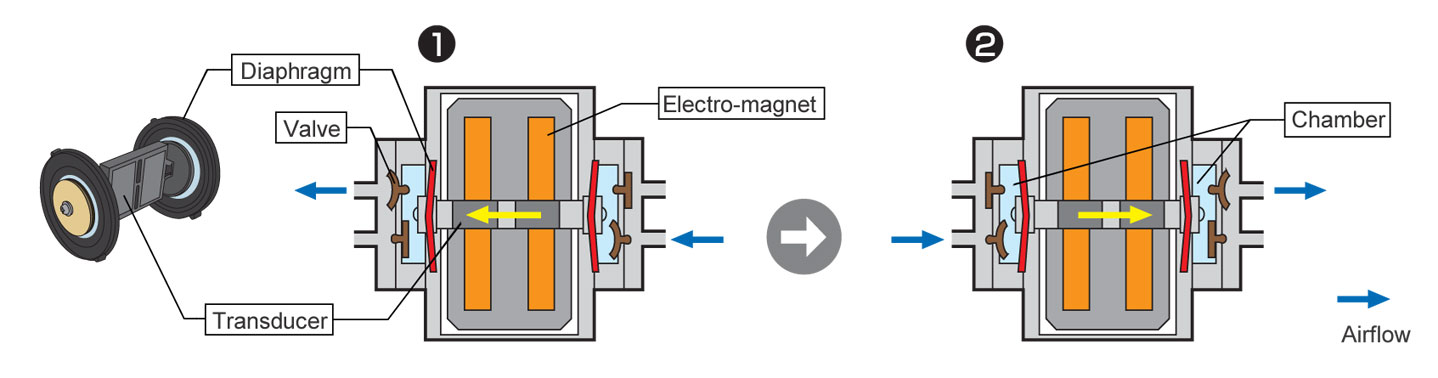

The change of polarity on the coil created by the AC power supply

causes a shuttling motion with the magnets.

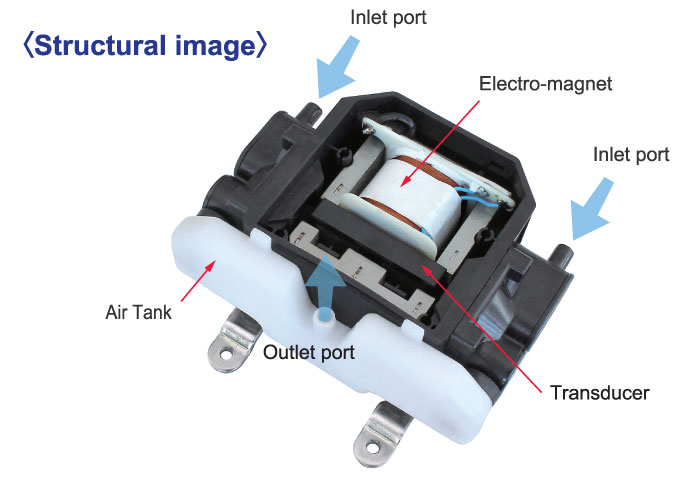

This shuttling motion allows the pump to alternately draw air in through the inlet

valve and then discharge air through the outlet valve.

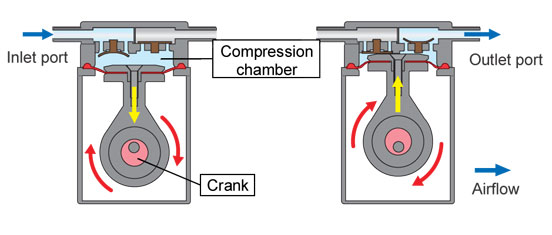

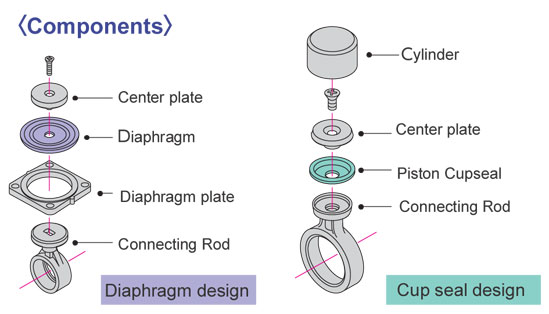

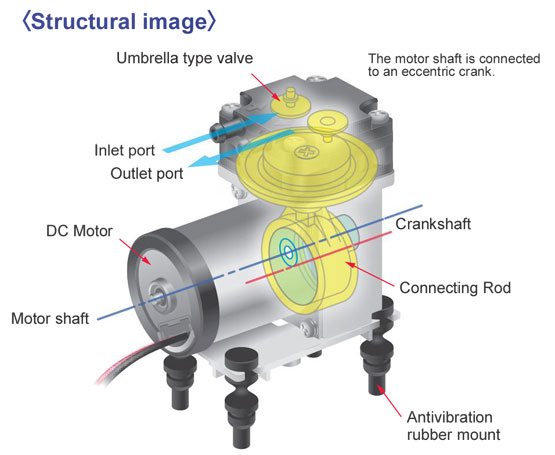

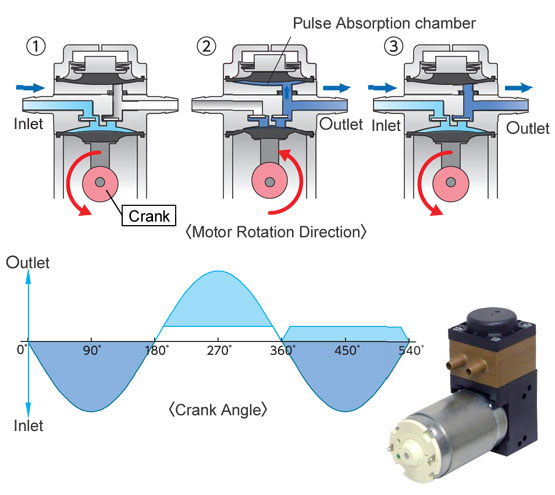

The reciprocating motion created by the connecting rod and rotating crank drive the diaphragm back and forth, drawing air in through the inlet port and out through the outlet port.

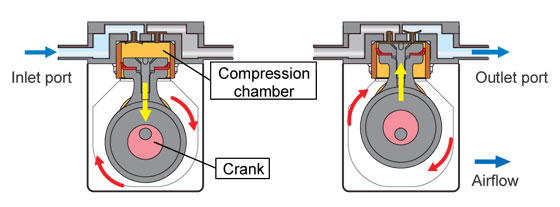

The reciprocating motion created by the connecting rod and rotating crank drive the cup seal back and forth, drawing air in through the inlet port and out through the outlet port.

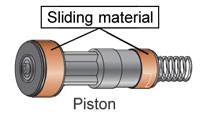

The cup seal creates a seal with the inner diameter of the cylinder as the piston pushes it back and forth.

Nitto Kohki incorporates the same know-how with the cup seal material as it does with pistons used in the linear compressors and vacuum pumps.

Pulses are attenuated through the process of 2 and 3

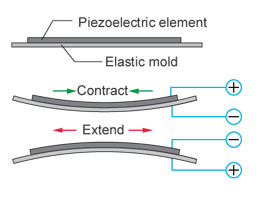

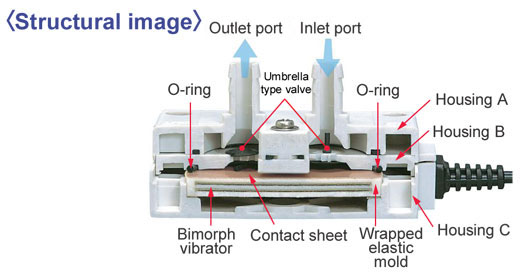

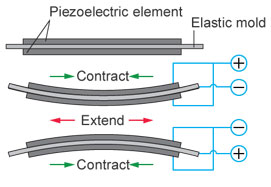

The BIMOR's driving force, the bimorph, is comprised of 2 parallel piezoelectric wafers.

The Unimor's driving force, the unimorph, is comprised of one piezoelectric wafer.

*Elastic mold Ceramic is affixed. The Bimorph and Unimorph are both circular. They contract and extend when powered.